CONSTRUCTION OF BORED PILES WITH PROPER TECHNIQUES

Bored Piles Construction – Solid Foundation Solution For Construction

Bored pile construction is one of the modern construction techniques, widely applied in Vietnam. With high load-bearing capacity, bored piles are the ideal choice for constructions on weak ground, bringing sustainability and safety to all projects.

Call Laya for Quotation now:  Call now : 9398564821

Call now : 9398564821

Or call Sumit for Quotation now:  Call now : 9128050538

Call now : 9128050538

Bach Khoa Construction Engineering Joint Stock Company is proud to provide professional bored pile construction services, ensuring proper techniques, safety and superior quality.

.png)

Correct technical sequence of bored pile construction.

1/ What is bored pile?

Bored piles are reinforced concrete piles, constructed by drilling a deep hole into the ground, then pouring concrete and compacting it. This type of pile has good load-bearing capacity, helping to transfer the weight of the structure to the hard soil layer deep below.

- Application: Residential buildings, high-rise buildings, bridges, roads, or construction works on weak ground.

- Benefits: Reduces subsidence, increases durability and stability of the structure.

.jpg)

Bored piles are a solid solution for your construction foundation.

Bored piles are often used in construction projects on weak soil, uneven ground or when it is necessary to transfer the weight of the structure to a deeper soil layer. Therefore, this construction technique has become a popular solution for many large and complex construction projects.

2/ Review the advantages and disadvantages of bored pile construction

Bored pile construction method has many advantages and disadvantages, which need to be carefully considered before applying to construction projects. Below are some points about the advantages and disadvantages of bored piles:

2.1. Advantages

- High load capacity: Suitable for hard soil layers and hard rocks that piles cannot reach.

- Noise and vibration reduction: Does not affect neighboring structures.

- Flexible in design: Adaptable to a wide range of geological conditions and technical requirements.

- Cost savings: No need to pre-cast piles, no time wasted welding steel bars.

.jpg)

Bored pile construction creates solid structures.

2.2. Disadvantages

- Difficult to check quality: The construction process is complicated and difficult to handle if errors arise.

- High cost: Requires specialized equipment and highly skilled labor.

- Weather dependent: Easily affected by storms, causing mud and construction interruptions

3/ Prepare work before construction

Before proceeding with bored pile construction, Bach Khoa Construction will prepare conditions to create the most favorable and quality working process. Preparation work usually includes site preparation, positioning bored pile centerline, and gathering equipment and materials. Including:

3.1. Site preparation

- Leveling the construction site before construction

- Geological survey to ensure technical factors, no machine subsidence during construction

- Develop the most suitable drainage plans to prevent heavy rain.

3.2. Locating bored pile centerline

This is an extremely important task, the project must determine the location of the axes, the center of the entire project and the exact location of all intersections, the axes. Based on that and the design documents to determine the core of each pile. Mark each pile center and column center position for convenience during construction.

3.3. Material gathering

Once the ground is leveled, materials and equipment are moved to the construction site. The assembly location must ensure convenience for the work process, and is usually located in high areas to avoid flooding.

.png)

Steps to carry out standard bored pile construction.

4/ Steps to carry out bored pile drilling

After the preparation work is ready, the bored pile drilling will be carried out according to the following steps:

Step 1: Lower the casing

Before drilling holes, Bach Khoa Construction will lower the casing to position and guide the drill, and at the same time, stabilize the surface of the borehole, prevent the components on the borehole from collapsing, and prevent rocks and equipment from falling into the borehole. The casing is lowered using a vibrator with a suitable diameter. The vibrator will clamp tightly to the wall of the pipe and lower itself, the shear capacity of the soil will decrease due to the shedding of the casing wall.

Step 2: Drill holes

After lowering the temporary casing, proceed to drill holes. The drilling process must always ensure the correct location of the hole to avoid deviations that affect the overall quality of the project. After drilling to a certain depth, Bentonite solution must be injected to maintain the wall, ensuring the quality of the borehole.

Step 3: Clean the borehole

After drilling the hole, the next step is to clean the entire borehole. The layer of drilling mud, soil and other construction materials in the borehole will affect the quality of the bored pile and hinder the construction process. In some cases of drilling concrete bored piles in the rain or in rainy weather, it is necessary to drain all the water in the hole, ensuring the hole is clean and free of stagnant water. Only then can the quality of the bored piles be guaranteed.

Step 4: Processing, assembling and lowering the steel cage

Steel cages at Bach Khoa Construction always ensure the correct size of the borehole. After cleaning the borehole will be lowered, assembled in the correct position on the design and ensure correct technical factors.

.png)

A step-by-step journey to create a solid foundation for your project.

Step 5: Proceed to pour concrete

This is the most important step and affects the overall quality of bored pile construction. Bach Khoa Construction always prepares and supervises this stage carefully and ensures the correct technical factors. The borehole must be dredged for less than 3 hours before concrete can be poured.

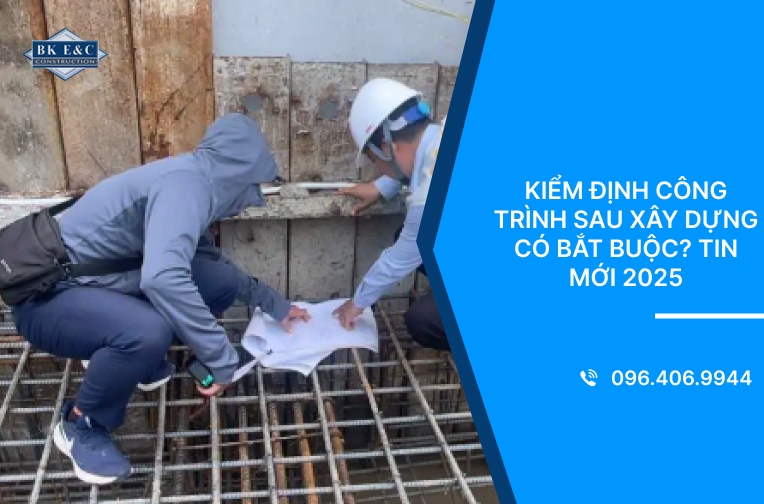

Step 6: Check pile quality

Inspection work is always meticulously performed by Bach Khoa to ensure the quality of the project, avoid errors and ensure the best conditions for the next construction.

5/ Things to note when constructing bored piles

When constructing bored piles, there are some important things to note:

- Prepare appropriate machinery and construction equipment. Helps save time and effort, while minimizing the possibility of incidents.

- For Bach Khoa Construction, safety is the top priority in every construction project. Must comply with labor safety regulations during construction and protective measures for workers.

- Ensure that all materials meet standards and are suitable for the project requirements.

- Bored pile construction must follow a specific process to ensure quality and efficiency.

- The bored pile construction process needs to be continuously checked and evaluated to promptly detect and correct any problems that may occur.

*****Bach Khoa Construction - Prestigious and quality bored pile construction unit*****

That is the entire bored pile construction sequence. Bach Khoa Construction Engineering Joint Stock Company is currently the leading prestigious bored pile construction unit in the market. We have a team of highly skilled technicians and workers who always ensure to bring the highest quality works, satisfying all customers. If you have a need for bored pile construction, please contact us immediately for advice on all information and the best service.

.jpg)

Bach Khoa Construction accompanies you in building the future on a foundation of quality and reputable bored piles.

BKEC is always willing to answer all questions and provide detailed information about products and services for customers in need. Please visit our website, call or email us for the best support. BKEC - Prestige and top quality!

Contact Now For Bored Pile Construction Consultation

Bach Khoa Construction Engineering Joint Stock Company is ready to accompany you in every project. Contact us now to receive a quote and detailed advice!

Call Laya for Quotation now:  Call now : 9398564821

Call now : 9398564821

Or call Sumit for Quotation now:  Call now : 9128050538

Call now : 9128050538

-

CERTIFICATE OF CONSTRUCTION CAPACITY LEVEL II: DESIGN, CONSTRUCTION, INSPECTION, TESTING, SUPERVISION

South: 361 Pham Van Bach , Ward 15, Tan Binh District, HCMC

Western Region: 86 Nguyen Trai, Cai Khe Ward, Ninh Kieu District, Can Tho City

Central Region: 16 Ton Dan, Loc Tho, Nha Trang

North: 32nd Floor, Suite 17, No. 54, Lieu Giai Ward, Cong Vi, Ba Dinh, Hanoi

![Chi phí kiểm định chất lượng công trình [cập nhập mới nhất 30 phút trước]](upload/baiviet/bkec3-1427.jpg)